Professional Tips on Implementing Foam Control in Chemical Handling Environments

A Comprehensive Guide to Applying Foam Control Solutions in Your Operations

Reliable foam control is a crucial aspect of operational performance that often goes forgotten. Recognizing the details of foam generation can dramatically affect both efficiency and product top quality. By checking out crucial aspects such as application compatibility and workers training, organizations can maximize their foam administration efforts.

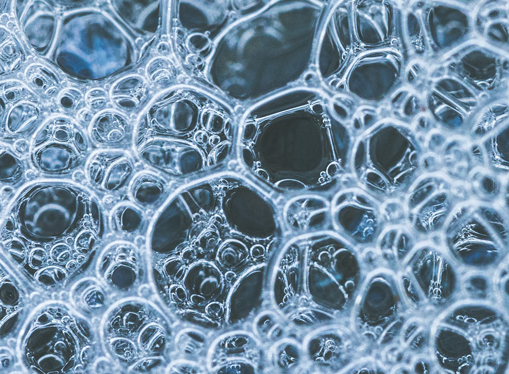

Understanding Foam Obstacles

Foam difficulties are a substantial issue across different sectors, influencing functional effectiveness and item high quality. The formation of extreme foam can prevent processes such as blending, transportation, and storage, leading to increased downtime and waste. In sectors like food and drink, pharmaceuticals, and petrochemicals, foam can disrupt production lines, causing product incongruities and contamination risks.

In addition, foam can obstruct tools performance, leading to pricey repairs and upkeep. In wastewater treatment, foam can interrupt clarifier procedures, resulting in reduced treatment performance and governing compliance issues.

Understanding the underlying reasons for foam generation is important for reliable management. Elements such as surfactants, temperature fluctuations, and frustration degrees can all add to foam production. Identifying these aspects permits sectors to execute targeted techniques that decrease foam development while keeping item stability.

Types of Foam Control Solutions

Mechanical solutions include making use of gadgets such as foam skimmers or defoamers. These tools physically remove foam from the surface of fluids, consequently preventing overflow and preserving optimal levels in storage tanks and reactors. Chemical remedies, on the various other hand, include the application of defoaming representatives-- substances that disrupt the foam framework, resulting in its collapse. These representatives can be silicone-based, natural, or aqueous, each offering distinct benefits relying on the application setting.

Lastly, functional methods focus on procedure modifications. This might include modifying tools specifications, such as temperature and stress, or altering the circulation rates of fluids to lessen foam generation. Furthermore, executing good housekeeping practices can also reduce foam formation by decreasing pollutants that contribute to foam stability.

Choosing the proper foam control service involves analyzing the details requirements of the operation, including the kind of procedure, the qualities of the materials entailed, and security considerations.

Picking the Right Products

Selecting the ideal foam control items needs a detailed understanding of the specific application and its special obstacles. Elements such as the kind of foam, the setting in which it happens, and the wanted result all play pivotal duties in product option. Foam Control. In industries such as food processing, it is critical to choose food-grade defoamers that abide with safety laws while efficiently taking care of foam.

Additionally, take into consideration the viscosity of the liquid where the foam trouble exists. Some items are formulated for low-viscosity applications, while others are tailored for thicker liquids. Compatibility with existing additional hints procedures is one more critical aspect; the chosen foam control representatives should integrate effortlessly without disrupting general procedures.

An additional crucial aspect is the approach of application. Some products may need dilution, while others can be used straight. Assessing the simplicity of usage and the called for dose can offer insights right into the item's performance and cost-effectiveness.

Implementation Techniques

Successful implementation techniques for foam control options need a methodical technique that lines up product option with functional requirements. The initial step includes a detailed evaluation of the procedures where foam happens, determining certain areas that necessitate intervention. By involving cross-functional groups, including production, high quality, and design guarantee, organizations can gather understandings that educate the choice of the most effective foam control items.

Next, it is essential to establish clear purposes for foam reduction, guaranteeing that these objectives are achievable and quantifiable. This may entail defining acceptable foam degrees and the timelines for implementation. Educating workers on the buildings and application techniques of selected foam control agents is equally crucial, as proper use is important for optimal outcomes.

In addition, integrating foam Home Page control services right into existing operations requires cautious preparation. Inevitably, a well-structured strategy will certainly improve functional efficiency while efficiently handling foam-related obstacles.

Monitoring and Assessing Efficiency

Surveillance and reviewing the effectiveness of foam control services is necessary for making certain that implemented techniques produce the preferred results. This procedure includes methodical information collection and evaluation to examine the efficiency of foam control representatives and strategies. Trick efficiency indications (KPIs) need to be developed before execution, permitting for a clear standard versus which to gauge progression.

Evaluating effectiveness also requires regular evaluations of find more information foam control procedures and agent effectiveness. This can be achieved with sampling and testing, enabling operators to identify if current services are satisfying operational needs. It is critical to obtain comments from team members that engage with these systems daily, as their insights can reveal functional subtleties that quantitative data may overlook.

Ultimately, a structured surveillance and assessment structure aids recognize essential changes, making certain that foam control remedies stay efficient, affordable, and aligned with organizational objectives.

Verdict

In conclusion, effective foam control remedies are vital for maximizing operational performance and maintaining item quality. A complete understanding of foam challenges, integrated with the option of suitable items and implementation techniques, promotes the successful administration of foam generation.

Applying good housekeeping methods can additionally reduce foam development by lowering contaminants that contribute to foam stability.

Choosing the best foam control items calls for a comprehensive understanding of the certain application and its one-of-a-kind obstacles (Foam Control).Successful application approaches for foam control solutions need a methodical strategy that straightens product selection with functional requirements.In conclusion, effective foam control services are important for maximizing operational performance and keeping item top quality. A comprehensive understanding of foam difficulties, integrated with the choice of proper items and application methods, promotes the effective monitoring of foam generation